A SOLID DIMENSIONALIZATION STRATEGY BEGINS WITH THE ITEM MASTER. Size and weight data in the item master is notoriously unreliable because manufacturers rarely have a process for synthesizing the ever-changing sizes and weights of products. Although setting up an item master initially might be feasible, maintaining the accuracy can be virtually impossible, and it is not accurate enough to drive the best efficiency in packaging anyway.

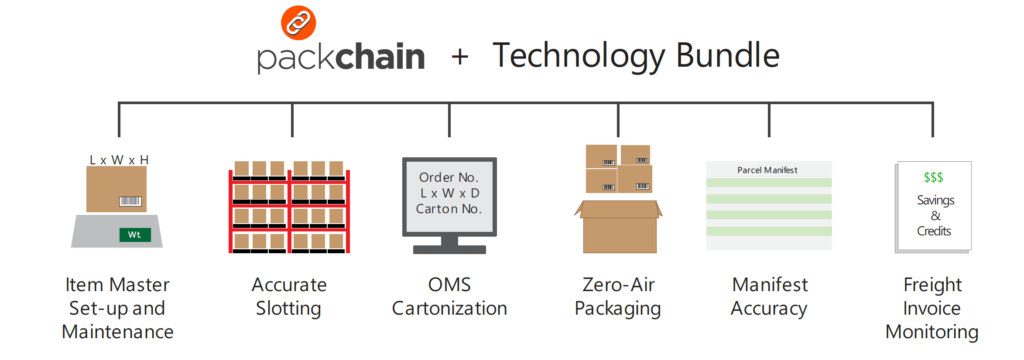

IQpack has hardware technology bundles, with packchain software as the backbone, to continuously monitor and update your dimensions and weights in the item master, keep the data clean and accurate in perpetuity, while validating (and correcting bad) bar code data at the same time.

IQpack Item Master Solutions Offering:

- In-line fully automated for singulated product flow

- In-line automated with QA station

- Semi-automated mobile unit

Packchain software can provide you complete visibility and chain of custody across your entire operation from item master, cartonization and packaging, through shipping.

There is no business case for shipping air in packages. Zero-air packaging systems are mature, improve throughput, and can dramatically reduce shipping costs. Packchain software integrates across your operations, using item master data to support zero-air and other packaging systems to optimize the size of the pack to reduce materials, improve sustainability, and ultimately reduce shipping costs. Savings displayed using your data.

For more information on our item master programs, packchain software, packaging solutions, or for shipping

savings opportunities, contact us at: http://www.iqpackglobal.com/contact.